What is ePTFE?

Polytetrafluoroethylene (or PTFE) is a particularly versatile ivory-white and opaque plastic fluoropolymer. It is created by the free-radical polymerisation of many tetrafluoroethene molecules, and is suitable for a wide range of applications in diverse industries such as medical, dental, aerospace, the food and drink industry, pharmaceuticals, telecommunications, and more.

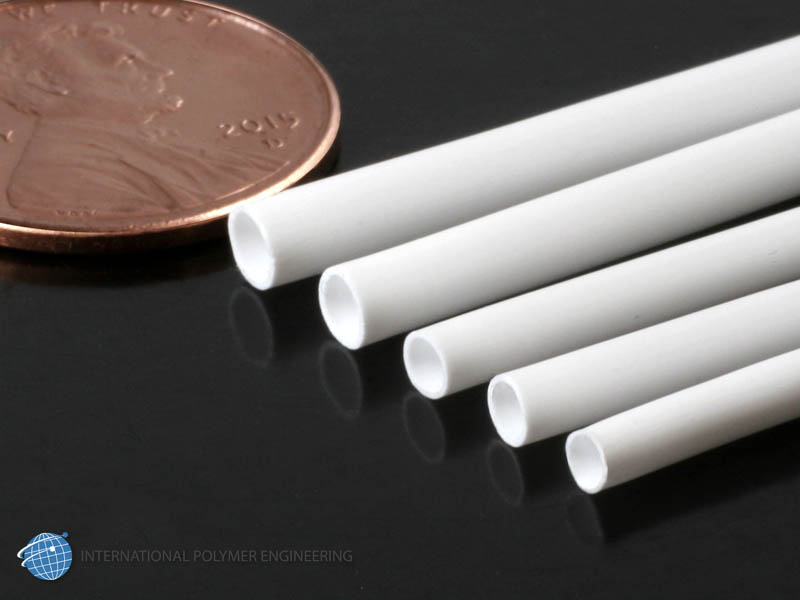

Fluoroflex™ ePTFE is a fully fluorinated polymer with exceptional chemical and physical properties: excellent chemical resistance, high temperature stability, good dielectric and non-stick properties and exceptional resistance to degeneration of mechanical properties under severe conditions. IPE’s proprietary Fluoroflex™ ePTFE is produced in sheets, rods, or tubes of almost any size; we can customize Fluoroflex™ ePTFE in a variety of densities to fit your individual application.

What are the benefits of using ePTFE?

The biggest advantage of ePTFE is its versatility and the range of applications it is used for. In addition, the number of different industries that can take advantage of this material is simply staggering. ePTFE can have massive benefits in both manufacturing and engineering however, its non-woven, open pore Fluoropolymer plastic is suitable for the critical demands of medical applications and other critical industries.

The physical and chemical properties can be critical to a variety of medical and non-medical applications in the form of tubes, rods, sheets, and specialty profiles. Current uses consist of synthetic arteries, implantable barrier membranes, hernia patches, facial implants, instrument covers, delivery tubes, among others. Very few non-woven plastics can meet or exceed the flexural properties needed in barrier, instrument delivery, and bending sections of typical medical implants and industrial instruments

In long-term medical applications, materials made from ePTFE can provide an anchoring system that promotes cellar ingrowth into the micro-structure with low extractable, high chemical resistance. ePTFE has been cited in medical research papers for its endothelization and thrombogenic properties.

Whether it is used for covering implants as a barrier or providing a soft supple capsule for implantation, ePTFE is rather unique. ePTFE does not contain any elastic properties that can alter flexural performance and stability of components or instruments. The qualities of high flexibility, chemically inert, biocompatibility, and low coefficient of friction provides unique and uncompromised performance of this material.

For industrial applications where high temperature, hydrophobic, chemical inertness, and high lubricity are needed, ePTFE has proven to be an excellent material for aeration, high-temperature sensor covers, low-pressure critical fluid passage, high-temperature gasket, chemical barriers, and nonstick cover applications.

What are the benefits of ePTFE?

It can be strong, rigid, thick, thin, flexible, or permeable combined with other properties depending on the ultimate use. It is a highly flexible, lubricious, chemically inert, hydrophobic plastic for critical applications.

ePTFE offers:

- Controlled variable porosity

- Withstands extreme temperatures

- Hydrophobic

- Chemically inert

- Biocompatible

- Low friction coefficient

- UV resistance

- High electrical insulation

- Non-flammable

- Dimensional stability

Why choose ePFTE for your project?

If you were trying to find a highly flexible, chemical resistant, thermal resistant, non-stick, and electrically resistant material, ePTFE is the answer you have been looking for!

Material made from expanded Fluoroflex™ ePTFE offers you more than the standard properties of PTFE. Expanded Fluoroflex™ ePTFE is soft, flexible and porous. Porous Fluoroflex™ ePTFE is permeable to air, yet watertight under low pressure. Its low coefficient of friction makes it ideal for applications requiring lubricity and durability.

The structure of porous Fluoroflex™ ePTFE is key. IPE manufactures material which can be collapsed longitudinally without significant change in external diameter as demonstrated in the video below.

Examples of Applications for ePTFE

- Aerospace (ePTFE wicks, wire harness sleeves)

- Aeration (controlled gas flow)

- Automotive (cable assemblies)

- Energy

- Filtration (vents)

- Medical (catheters, endoscopic working channels)

- Telecommunications

- And many more

Chemical and Physical Properties

- Excellent resistance to caustic chemicals

- Low dielectric constant

- Low coefficient of friction

- Non-flammable

- Service temperature range: -240° to +250°C

Characteristics

- Biocompatible

- Flexibility

- Kink resistance

- Softness

- Weather resistant

If you are interested in FluoroFlex™ ePTFE for any of your projects, or if you’d like to find out more information about the properties of ePTFE, please contact us and let’s chat about your application.

(877) 410-3265