ePTFE is one of the most innovative variations in the processing and application of PTFE. The porous structure is engineered to have pores small enough to keep water molecules out but still large enough to let air and vapor pass through.

ePTFE has many small pores on the membrane due to the way it is manufactured, which involves mechanically stretching it on the microscopic level. The material is porous, flexible, lightweight, and hydrophobic (water pressure up to 8-10 PSI) which makes it extremely useful in a variety of filtration and separations applications. It is chemical and fire resistant as well as water and UV resistant. It is also extremely flexible, meaning you can insert it into a variety of applications without worrying about cracking or creasing the material.

ePTFE is the perfect material for:

- Medical (sutures, vascular components, endoscopic working channels)

- Implants

- Lightweight, waterproof, and breathable fabrics

- Aeration (controlled gas flow)

- Micro-porous membranes

- Automotive (cable assemblies)

- Aerospace (PTFE wicks, wire harness sleeves)

- Filtration (vents)

- And many more

FluoroFlex™ ePTFE

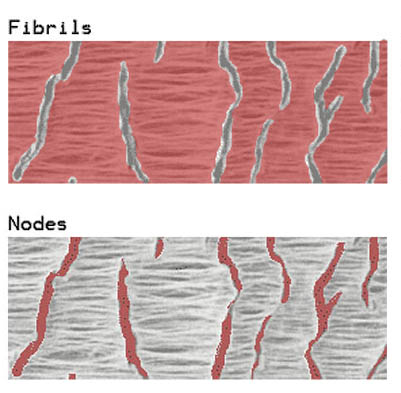

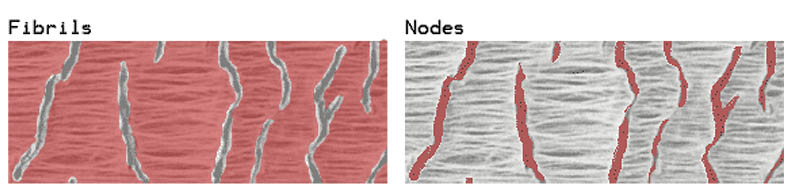

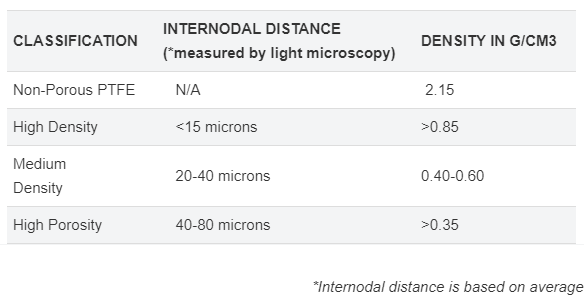

The microstructure of FluoroFlex™ ePTFE can be described as roughly parallel-running clumps of material (nodes) with perpendicular fibers connecting them. Fibers connected between the nodes are called fibrils. Porosity is a function of the distance between the nodes. See figure 1 below. As the internodal distance decreases, porosity decreases. Conversely, as the internodal distance increases, porosity increases. Porous ePTFE can also be classified in volume densities. IPE has the capability of producing ePTFE in volumes densities ranging from 0.30 to 1.3 grams per cubic centimeter. Higher density ePTFE would be less porous and more rigid lower density would be more porous and flexible.

Figure 1: The microstructure of FluoroFlex™ ePTFE.

Porous ePTFE can also be classified in volume densities. IPE has the capability of producing ePTFE in volumes densities ranging from 0.30 to 1.3 grams per cubic centimeter. Higher density ePTFE would be less porous and more rigid lower density would be more porous and flexible.

Material made from expanded FluoroFlex™ ePTFE offers you more than the standard properties of PTFE. Expanded FluoroFlex™ ePTFE is soft, flexible and porous. Porous FluoroFlex™ ePTFE is permeable to air, yet watertight under low pressure. Its low coefficient of friction makes it ideal for applications requiring lubricity and durability.

Classifications

What can we help with?

FluoroFlex™ ePTFE Sheets

IPE manufactures ePTFE sheet to customer specifications from 0.05mm to 6mm in thickness and a wide variety of material porosities to fit specific application requirements. ePTFE sheet is the material of choice for a variety of applications including dental barriers and implants, barrier membranes, facial implants, venting, gasketing and chemical or temperature barriers to name a few. ePTFE sheet is cut into blanks for fabricating into smaller parts.

FluoroFlex™ ePTFE Rods

IPE manufactures ePTFE rods to customer specifications from 0.20mm to 9.5mm O.D. and can be spooled or cut to length. Rods are extruded of ePTFE and are used for all kinds of medical, chemical, electrical and mechanical components where the outstanding performance characteristics of ePTFE are required. ePTFE rods are the material of choice for a variety of applications including sutures, strain relief devices, facial implants, sewing thread, filtration, and wicking devices to name a few.

FluoroFlex™ ePTFE Tubes

IPE manufactures ePTFE tubes to customer specifications from 0.7mm to 22mm I.D. with wall thicknesses ranging from .05mm to 1mm. Tubes are extruded in ePTFE and are used for medical, chemical, electrical and mechanical components where the outstanding performance characteristics of ePTFE are required. ePTFE tubing is the material of choice for a variety of applications including bending sections, instrument covers, stent covers, endoscopic working channels, ozone delivery, vascular devices and aeration and deaeration of caustic fluids to name a few.

When looking for a highly flexible, lubricious, chemically inert, hydrophobic plastic for critical applications, very few non-woven plastics can meet or exceed the flexural properties needed in barrier, instrument delivery, and bending sections of typical medical implants and industrial instruments like our FluoroFlex™.

Want to get started on your custom product? Request a Quote from IPE today!

www.ipeweb.com | 877-410-3265