IPE manufactures and distributes custom profile extrusions made from Fluoroflex™ porous polytetrafluoroethylene (ePTFE). We use the latest in polymer techniques to reduce costs and shorten lead times for the manufacture of small diameter tubing. IPE uses Fluoroflex™ ePTFE to extrude materials to customer established specifications.

Our first commitment is to our customer's satisfaction. We achieve this by maintaining quality components and customer service. IPE's customer service representatives are friendly and experienced; they can aid in the development of your current or new applications. Our Quality Department maintains the high quality of our components by rigorously testing them to ensure they match our customer's specifications.

Extensive records are maintained throughout the manufacturing process per the ISO document system. Our system ensures complete traceability of all OEM components manufactured by IPE.

Fluoroflex™ ePTFE Sheets

IPE manufactures ePTFE sheet to customer specifications from 0.05mm to 6mm in thickness and a wide variety of material porosities to fit specific application requirements.

ePTFE sheet is the material of choice for a variety of applications including dental barriers and implants, barrier membranes, facial implants, venting, gasketing and chemical or temperature barriers to name a few. ePTFE sheet is cut into blanks for fabricating into smaller parts.

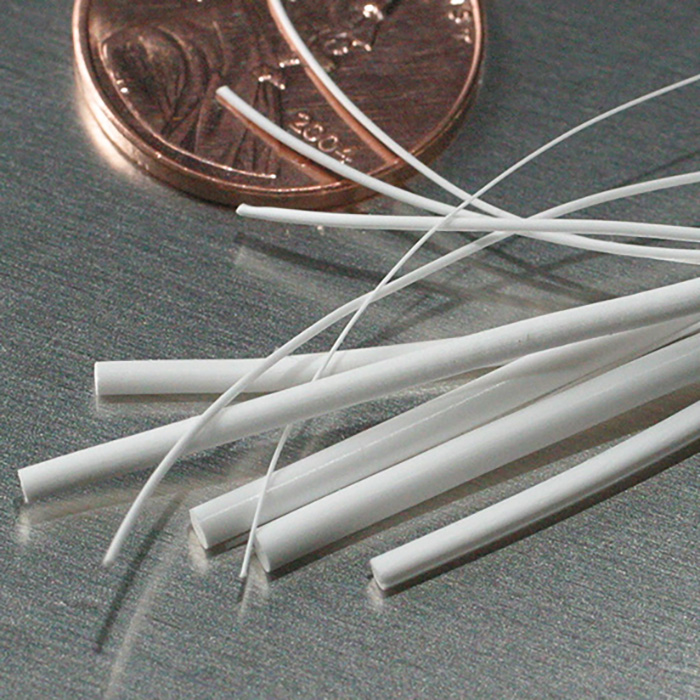

Fluoroflex™ ePTFE Rods

IPE manufactures ePTFE rods to customer specifications from 0.20mm to 9.5mm O.D. and can be spooled or cut to length. Rods are extruded of ePTFE and are used for all kinds of medical components where the outstanding performance characteristics of ePTFE are required. ePTFE rods are the material of choice for a variety of applications including sutures, strain relief devices, facial implants, sewing thread, filtration, and wicking devices

(to name a few).

Fluoroflex™ ePTFE Tubes

IPE manufactures ePTFE tubes to customer specifications from 0.7mm to 22mm I.D. with wall thicknesses ranging from .05mm to 1mm. Tubes are extruded in ePTFE and are used for medical components where the outstanding performance characteristics of ePTFE are required. ePTFE tubing is the material of choice for a variety of applications including bending sections, instrument covers, stent covers, endoscopic working channels, ozone delivery, vascular devices and aeration and deaeration of caustic fluids

(to name a few).