PTFE was discovered by accident in 1938 while an engineer was attempting to make CFC refrigerant. This unique combination of carbon and fluorine created the highest electronegativity of all of the elements. The relationship between the bond polarity of carbon and fluorine combined to provide the lowest surface energy among organic polymers. It is also the most chemically resistant organic polymer, thermally resistant, and offers a high melting temperature.

We call our proprietary ePTFE superior plastic material FluoroFlex™. ePTFE (or expanded PTFE) is a processed form of polytetrafluoroethylene (the chemical name for a unique plastic with extraordinary material properties) and is a non-woven, open pore Fluoropolymer plastic, suitable for the critical demands of medical applications and other industries.

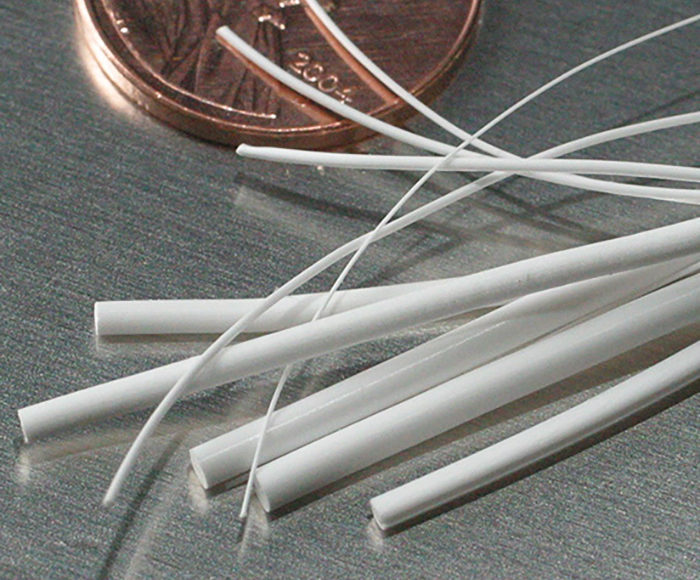

These physical and chemical properties can be critical to a variety of medical and non-medical applications in the form of tubes, rods, sheets, and specialty profiles. Current uses consist of synthetic arteries, implantable barrier membranes, hernia patches, facial implants, instrument covers, delivery tubes, among others.

In long-term medical applications, materials made from ePTFE can provide an anchoring system that promotes cellar ingrowth into the micro-structure with low extractable, high chemical resistance. ePTFE has been cited in medical research papers for its endothelization and thrombogenic properties.

Whether it is used for covering implants as a barrier or providing a soft supple capsule for implantation, ePTFE is rather unique. ePTFE does not contain any elastic properties that can alter flexural performance and stability of components or instruments. The qualities of high flexibility, chemically inert, biocompatibility, and low coefficient of friction provides unique and uncompromised performance of this material.

For industrial applications where high temperature, hydrophobic, chemical inertness, and high lubricity are needed, ePTFE has proven to be an excellent material for aeration, high-temperature sensor covers, low-pressure critical fluid passage, high-temperature gasket, chemical barriers, and nonstick cover applications.

Why chose FluoroFlex™?

It can be strong, rigid, thick, thin, flexible, or permeable combined with other properties depending on the ultimate use.

Its physical properties include:

- Controlled variable porosity

- Withstands extreme temperatures

- Hydrophobic

- Chemically inert

- Biocompatible

- Low friction coefficient

- UV resistance

- High electrical insulation

- Non-flammable

- Dimensional stability

When looking for a highly flexible, lubricious, chemically inert, hydrophobic plastic for critical applications, very few non-woven plastics can meet or exceed the flexural properties needed in barrier, instrument delivery, and bending sections of typical medical implants and industrial instruments like FluoroFlex™.